RFID Tags Australia: RFID Tags Australia Perks for Inventory Management

Using RFID to track and manage inventory eliminates human scanning errors, improper logging in spreadsheets and missing information. It also saves time by eliminating manual processes and allows for real-time data on the status of all items.

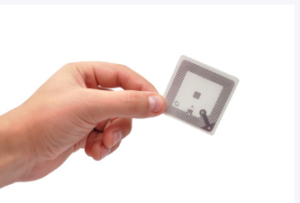

Unlike barcodes, RFID tags Australia don’t need a direct line of sight to be read. It speeds up the checkout process and frees employees to help customers.

Unlike barcodes, RFID tags Australia don’t need a direct line of sight to be read. It speeds up the checkout process and frees employees to help customers.

Improved Inventory Management

Efficient inventory tracking is a crucial part of any warehouse operation. Using RFID tags to automate and streamline the tracking process can significantly reduce labour costs while improving accuracy and efficiency. Unlike barcode scanners, RFID technology does not require direct line-of-sight to read, which allows for improved visibility and faster scanning speeds.

For manufacturers that produce and deliver many different products, keeping accurate stock counts is a big challenge. Without an efficient and reliable tracking system, inventory can quickly go out of control, leading to expensive losses. RFID technology can help companies avoid these costly mistakes by allowing them to track their inventory in real-time.

Whether it’s components on the production line, finished goods being shipped, or high-value business assets like test equipment, field tech, or portable computer technology, maintaining tight control of inventory is critical to any organization. RFID tags make this easier by automatically tracking and logging items in your database, eliminating the need for manual counting, data entry errors, or inventory management software crashes from too many updates at once.

In addition, RFID tag data can be accessed at any time — even under layers of paint and plastics, which improves the ability to use this information in production processes such as scheduling and workflow optimization. For example, a quick scan can determine where an item needs painting or what parts need to be swapped out. It helps to streamline the production process, ensures that the right parts are in place for a particular job and reduces overall downtime.

Reduced Costs

For companies that use a returnable fleet of containers and pallets, RFID tags Australia can help to reduce costs. By integrating RFID into these assets, businesses can track them throughout their entire supply chain cycle, reducing the risk of lost or stolen inventory. Similarly, RFID tags can be integrated into manufacturing machines to ensure that the correct parts are selected and assembled to create finished goods, which could reduce overall production costs.

Warehouses can also see reduced labour costs with RFID solutions. The ability to read multiple tags at once with a single scanner eliminates the need for manual searches, which can save employees significant time. Additionally, the ability to perform cycle counts from a distance helps lower labour costs by limiting the need for physical inspections and reordering at safety stock levels.

Increased Customer Satisfaction

Whether you’re shipping directly to customers or providing in-store pickup, RFID can streamline and automate your processes. It eliminates manual scanning, reducing labour costs and eliminating human error. It also reduces warehousing costs by optimizing storage space and inventory tracking.

Compared to barcodes, RFID tags can be read more quickly and at greater distances, allowing you to track and monitor assets from a variety of positions. You can also scan multiple tags at once — unlike barcodes, which require you to scan them individually. And, because RFID doesn’t require a physical connection between the tag and the reader, it can be used in a variety of environments where you might not want to touch an item — like on a conveyor belt or through a doorway.

Improved Security

When you use RFID tags, data is automatically transmitted and uploaded to a system. It eliminates the need for human scanning and logging, which can lead to errors like missing information, inaccurate records and slow processes. This streamlines operations and improves accuracy, efficiency and accountability across your supply chain.

In addition, RFID tags Australia do not need a line of sight, so tagged items can be read even if other materials or obstacles obscure them. It allows for faster processing of inventory and a reduction in labour costs. It also eliminates the need for manual entry into spreadsheets, which reduces transcription errors and duplicated or mismatched data.